SUSTAINABLE RAW MATERIALS

37

37 materials assessed based on materials’ importance for industry and associated ESG risks

By coming together and developing a shared perspective on some of the most critical ESG issues in the automotive supply chain, Drive Sustainability is building a coordinated approach toward the responsible sourcing of raw materials.

One of the biggest obstacles in setting strategies for responsible sourcing is:

- • the access to reliable current data and analysis on the environmental and social dimensions of material production

- • the complexity and lack of transparency of the automotive supply chain

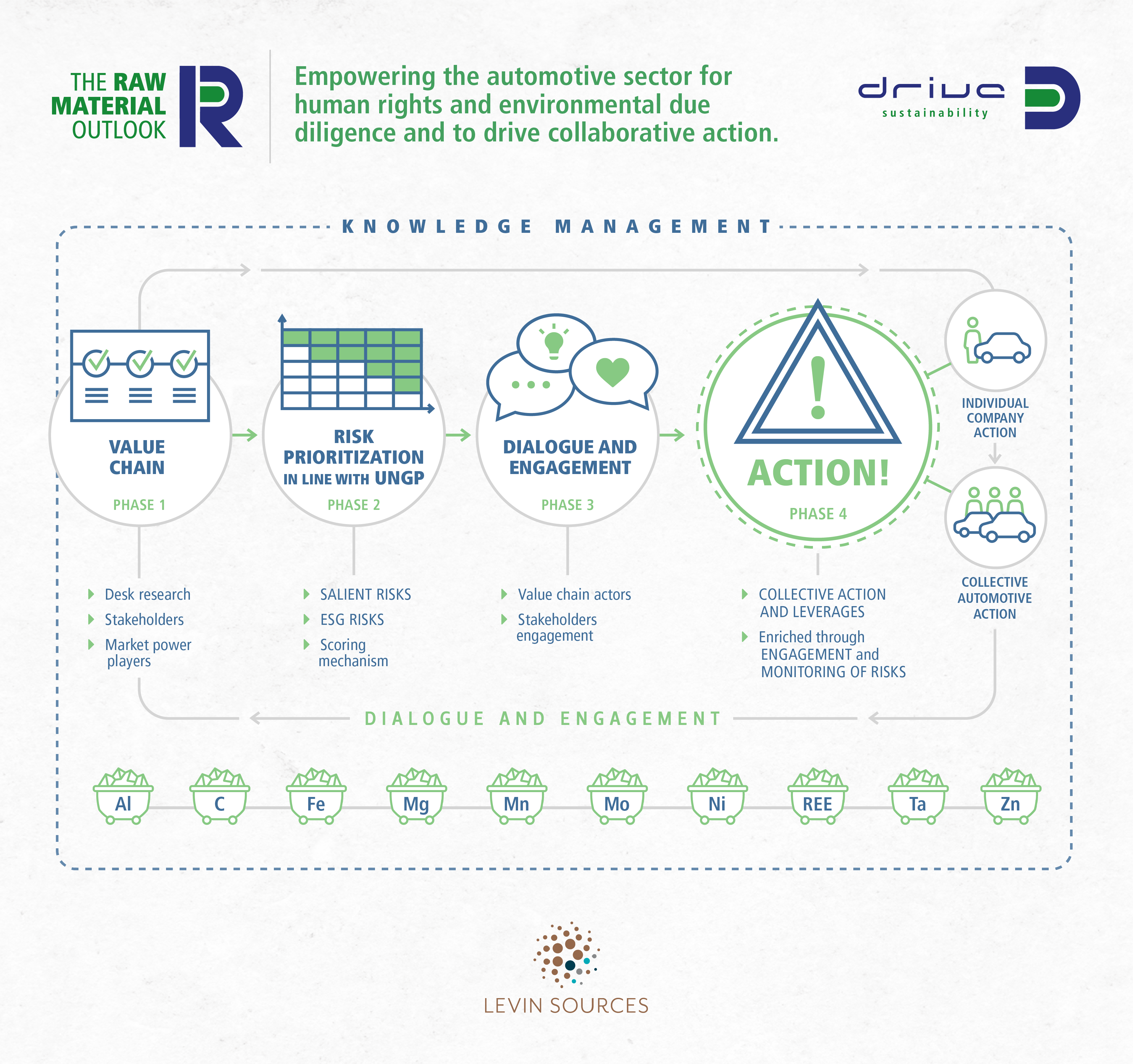

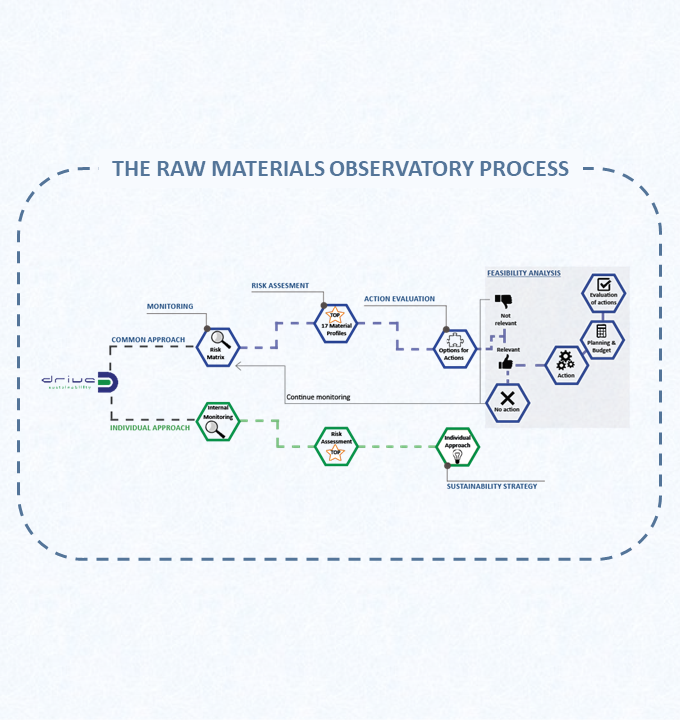

To address these challenges, Drive Sustainability has developed the Raw Materials Observatory: a toolbox of instruments to identify risks and impacts in the minerals’ supply chains, as well as a standardized process to identify opportunities for collective risk mitigation and remediation.

Learn more about the observatory and the instruments (Raw Material Outlook, Material Change Report) feeding into the observatory below.

OUR ACTIVITIES

The Raw Materials Observatory is a process to:

• assess the sustainability risk of the top raw materials for the automotive sector

• identify potentially impactful activities that Drive Sustainability partners could pursue collectively to address such risk

Collective action will complement what Drive Sustainability partners are doing at the company level to integrate sustainability in the sourcing of raw materials.

In 2021 Drive Sustainability launched Raw Material Outlook (RMO), the platform dedicated to managing and mitigating the Human Rights violations and the ESG impacts of materials used in the automotive value chain. The platform was commissioned by Drive Sustainability and completed by Levin Sources.

This Drive Sustainability initiative empowers the automotive industry’s environmental and social due diligence and fosters sector and multi-stakeholder collaboration. It is a first step for unpacking each material value chain by mapping each stage, outlining principal actors, and identifying the most salient ESG risks.

The RMO provides a tool for individual automotive companies and the Drive Sustainability group to analyse materials’ value chains and advance responsible sourcing endeavours.

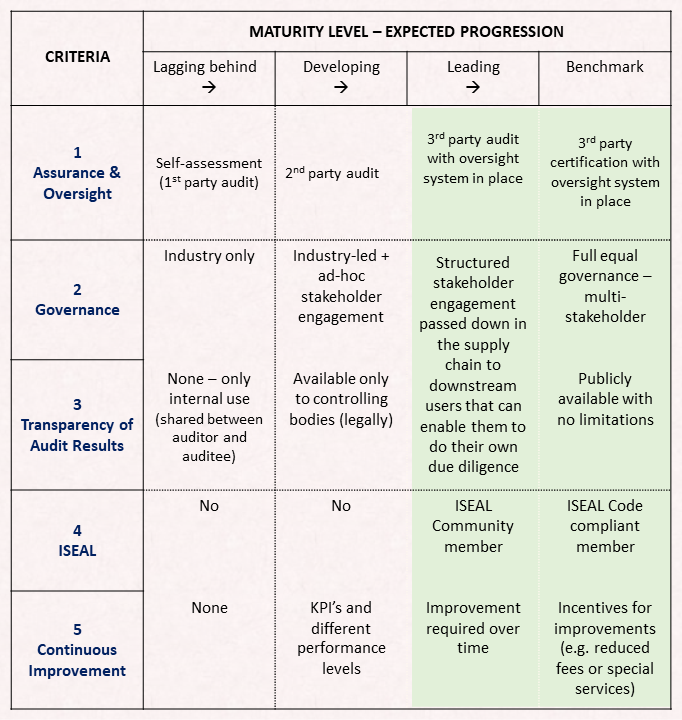

In 2021, Drive Sustainability launched the Common Standards Recognition Framework, a set of criteria to assess the maturity level of sustainability standards in the minerals supply chain. The main idea of the common standards recognition lies within the common voice of Drive Sustainability. Our ambition is to send a coherent and unified message to our suppliers and stakeholders, to promote standardization, common and/or similar approaches throughout the value chain.

Following a Stakeholder Dialogue, held in October 2023, the Common Standard Recognition Framework will be reviewed in 2024.

There are five key criteria around which the common standards approach was built:

- 1) Assurance and oversight

- 2) Governance

- 3) Transparency of audit/certification results

- 4) ISEAL membership

- 5) Continuous improvement

Drive Sustainability engaged with more than 20 stakeholders, including suppliers, NGOs, industry associations, trade unions and upstream actors, and delivered capacity-building activities with the Drive+ members.

Furthermore, to improve the social & environmental situation on the ground, Drive Sustainability supported CSR Europe in the project Extractives for Sustainability, with the aim of establishing local sustainability networks of mining companies and their suppliers in the Democratic Republic of Congo (Copper and Cobalt) and South Africa (Manganese and Iron Ore), by empowering the local industry associations.

In 2023, Drive Sustainability joined forces with IndustriALL, a global federation of trade unions, to deliver a pilot project addressing workers’ rights in Nickel production in Indonesia.

Our milestones

| 2020-2025 | 2025-2030 |

|

|

News

The Importance of Engaging all Stakeholders along the Value Chain to Foster Responsible Mineral Supply Chains

Drive Sustainability engaged high-level stakeholders at the 2023 OECD Forum on Responsible Mineral Supply Chains in Paris, emphasizing the crucial interplay between the EU policymakers, supply chain...

Read moreDigging Deeper into Responsible Sourcing: Our Lessons from the Stakeholders’ Engagement in the DRC

Between 12-20 June, Drive Sustainability engaged with key stakeholders like the DRC Chamber of Mines, the Employer Federation of Congo, mining companies and development agencies in the Democratic Re...

Read moreFurther resources